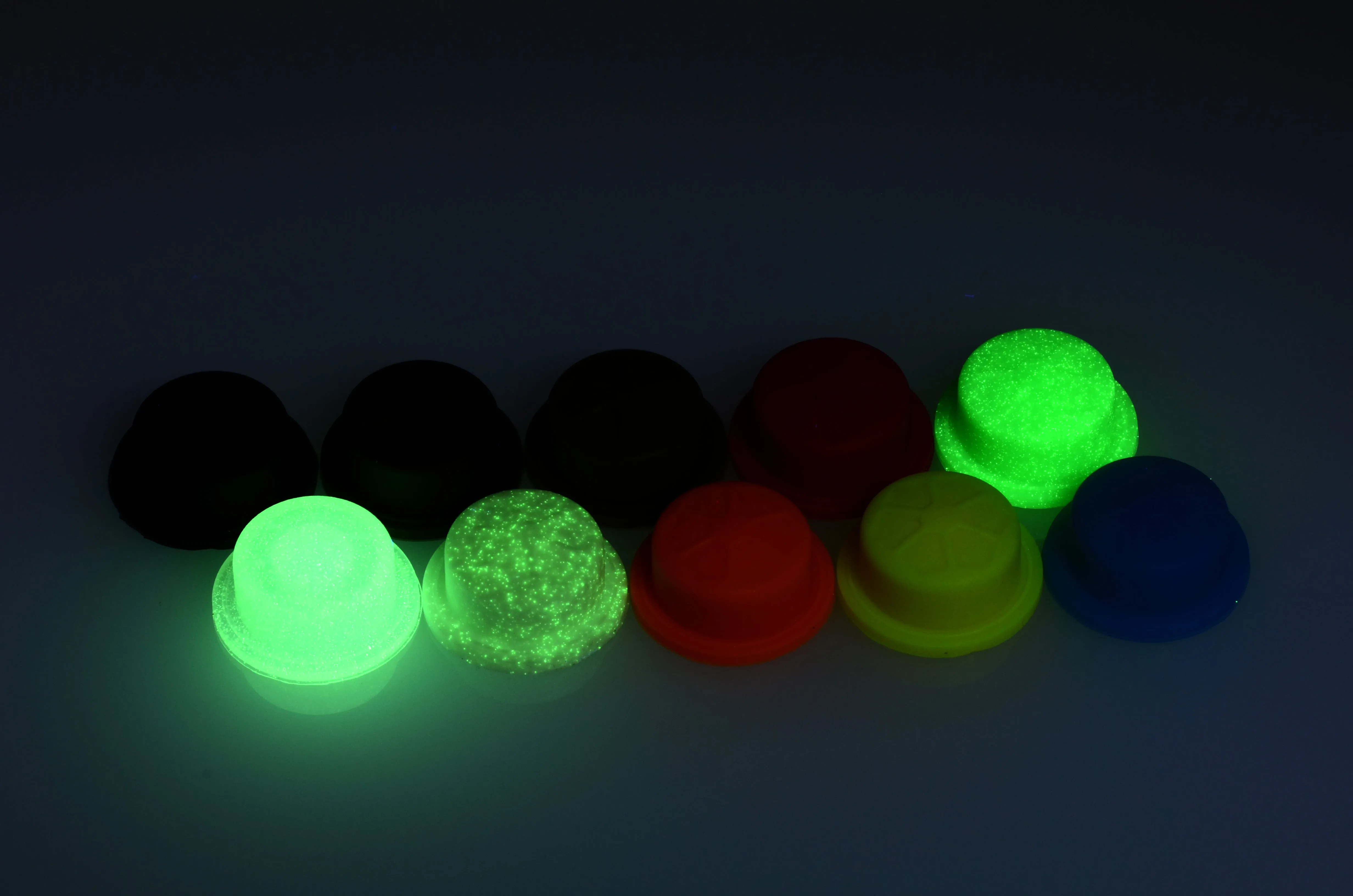

The Alpha MIL/LEO is a modified Ready Made body, and you get to pick your LED just like with the Custom lights.

Alpha lights are assembled to order and may take up to two weeks to ship, depending on our current workload.

When you place an order you'll be asked to provide credentials before we begin the build. You can also place your order using an "official" email address to qualify. |

As you know I don't make "tactical" flashlights because I don't engage in hype. Furthermore, I would never call a flashlight "tactical" without direct design input from the MIL/LEO community. However, I do have many MIL/LEO customers who believe the Alpha is an excellent duty light, because every aspect is well balanced and I don't take any shortcuts.

The reason I'm making a "black" flashlight is because those same MIL/LEO customers often request that for a variety of reasons. Remember that direct design input? Yep.

Please note: While the Alpha MIL/LEO shares many similarities with the rest of its Alpha cousins, you should consider this light a prototype that has NOT been fully field tested. That job, and the degree to which you will rely on it, is yours.

I've been working on this driver for over two years. It's simple, powerful, and full of features even the most demanding flashlight enthusiasts will appreciate. A maximum current of 3.4 Amps delivers class-leading power and an advanced software platform lets you make Icarus a reflection of your unique preferences by programming it any way you like...

This driver is 100% designed, programmed, and manufactured (in the USA) just for me. Until now, I've been limited by "what is available," but Icarus is the realization of a long standing goal. No expense is spared, no shortcuts taken, no compromise accepted. I'm proud to put the Prometheus stamp on this driver as the crowning jewel of the Alpha platform. Enough talk, let's get to the details.

One feature of Icarus that is specifically oriented towards MIL/LEO users is what I call "digital drop protection." Most tail switching lights will "jump" levels if they are dropped or struck in such a way that the battery momentarily disconnects from the battery contacts. Basically the light thinks the button has been pushed when it has not. Icarus is programmed to sense the difference between and accidental disconnect (dropping the light) and an intentional disconnect (pressing the button); meaning the light will NOT shift levels during an impact.

This software feature also allowed me to eliminate the usual spring-contact. These springs are typically made from carbon steel and have very high resistance. I have implemented a solid copper battery contact that has outstanding electrical conductivity.

Since this is a MIL/LEO oriented light, Alpha lights have a "standard" 1 inch diameter body that is compatible with most after-market weapon mounts. I'll also mention that the "digital drop protection" prevents recoil induced mode switching. I know, cool right?

The Alpha MIL/LEO fluting and crenelation is done in-in house, while the otherwise "Ready Made" body is machined at my local shop. Fluting provides additional anti-roll protection and the crenelations allow you to see if the light is on when it is standing on the head, ideally preventing accidental light exposure. Fluorosilicone o-rings are used throughout because of their indefinite shelf life and ability to resist fuels and corrosives.

When you order a MIL/LEO Alpha you can choose your LED, but I still recommend the "Maker's Choice" MCE 4500K LED. I have two theories on this. First, these are 82 CRI minimum and I believe the enhanced color rendering will allow your brain to recognize features and make decisions more quickly. It's just a theory, but when life demands split second decision making, I want to reduce the workload on my brain as much as I can.

Second, I'm with on this one, a floody light is preferable for "scanning" because it allows better use of peripheral vision and prevents target fixation that you get with a more focused beam. He starts talking about it around 6:00 into the video. Obviously if our task requires long-range search, this isn't the right light. If you are looking for massive illumination at 100 feet and closer, nothing will beat this light.

Finally, please check out this beam shot comparison video (above). It's video is old, but clearly illustrates the difference between the Alpha performance/philosophy compared to a very well known tactical flashlight. One good thing about the floody beam is that you can put out a ton of lumens at close range and not be blinded by reflections, while overwhelming the visual system of anyone down range.

Notes on the PVD coating: I sent out a survey asking if people wanted a raw titanium colored clip or if they would prefer a black PVD clip to match the light. Not surprisingly most people opted for the black PVD clip. Because PVD is very expensive, I've made the black clip an additional option; otherwise the light will come with a standard raw titanium clip.

I want to be clear, this coating is not DLC (diamond like carbon), but simply a black PVD.

First, PVD is Physical Vapor Deposition and describes a method of coating, not the type of coating. Many materials can be applied with the PVD process.

Second, DLC is about 3x more expensive than this black PVD. The current coating for one light costs me $100 and coating one clip costs me $25. As you can see, this is very expensive, and I am not charging any markup on the coating process. The difference in price represents the actual cost.

Third, the coating is only microns thick and any coating is only as durable as the substrate. In this case we have aluminum, which is not a very hard material. It would be a waste to put DLC onto the light (I know you will ask) because you don't actually gain any durability. The Alpha MIL/LEO is first plated with Electroless Nickel then PVD coated. This is about as good as you are going to get on aluminum.

Finally, why didn't I just black anodize the light like everyone else? Because it makes no sense and here is why: The body of the light needs to conduct electricity to complete the circuit. When lights are anodized, you have to machine off (remove) the anodize to make electrical contact (by exposing bare metal) because the anodize layer is an excellent electrical insulator. Aluminum oxidizes readily when exposed to air, moisture, and salt. So, you have just removed the protective coating from the most important area of the flashlight to protect; the parts that conduct electricity.

Cart(

Cart(